Volumetric 3D-printing is an emerging additive manufacturing technique which vastly increases printing speed and enhances surface quality by bypassing the stepwise ink renewal step in conventional 3D-printing.

Conventional methods for 3D-printing polymers typically use focused light to induce photopolymerization and solidfy an object. The use of light causes several limitations, key among which are limits to material choice and build size. Furthermore, using light to cure these objects inhibits volumetric printing deep inside the body, as focused light cannot reach much further than the optical diffusion limit (~1 mm in biological tissue).

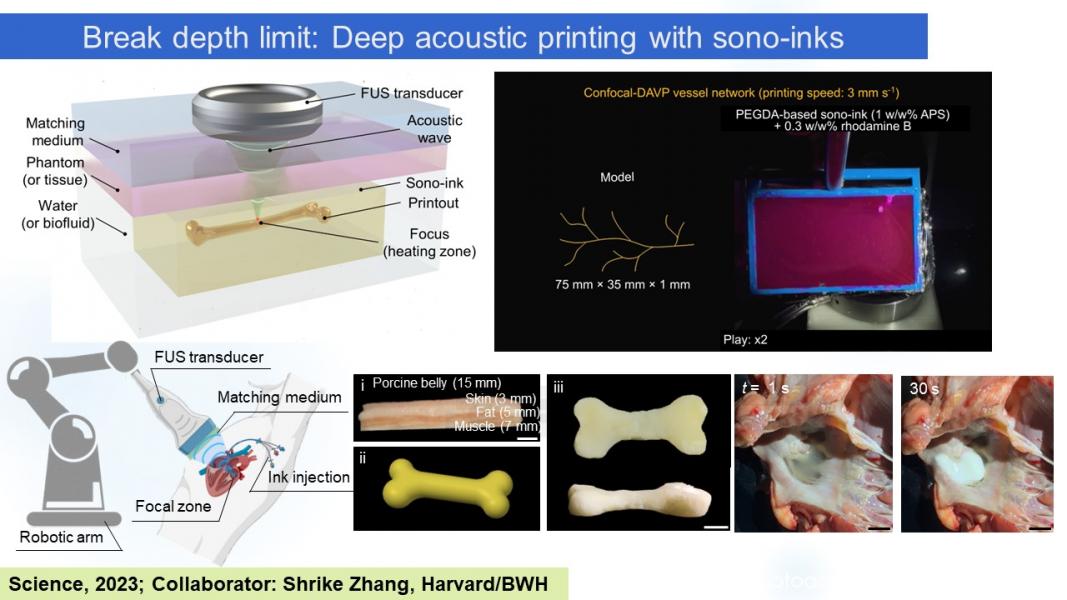

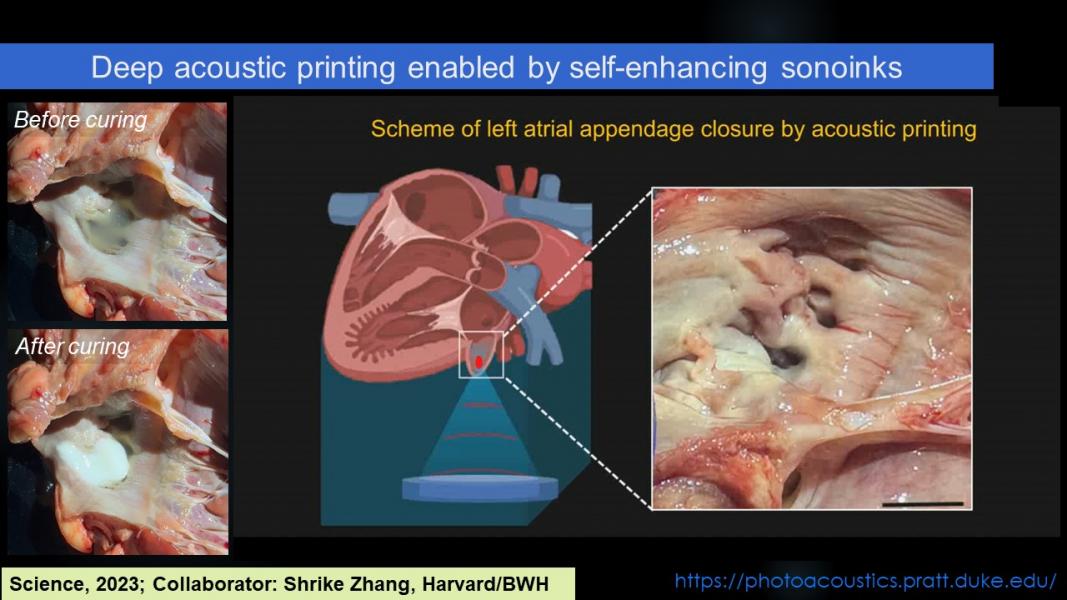

Collaborating with doctors from Harvard Medical School, the Photoacoustic imaging lab has developed a new method to 3D-print polymers called "deep volumetric acoustic printing". By leveraging high-intensity focused ultrasound and a novel sonicated ink, or SonoInk, we are able to print objects with high speed and depth. The use of ultrasound waves and the sonothermal effect for 3D printing can allow for up to a 100 times increase in penetration depth over light whilst retaining spatial precision.

To learn more about this new technology and its exciting results, please visit the link to Science below.